CNC Milling

Turning and milling operations should be trusted by professionals in China

Advanced equipment

5-axis machining centers

High precision

Accuracy up to: ±0.005mm

High efficiency

Improving production efficiency

Cost reduction

Suitable for all types of production and processing

Providing quality CNC milling services in China

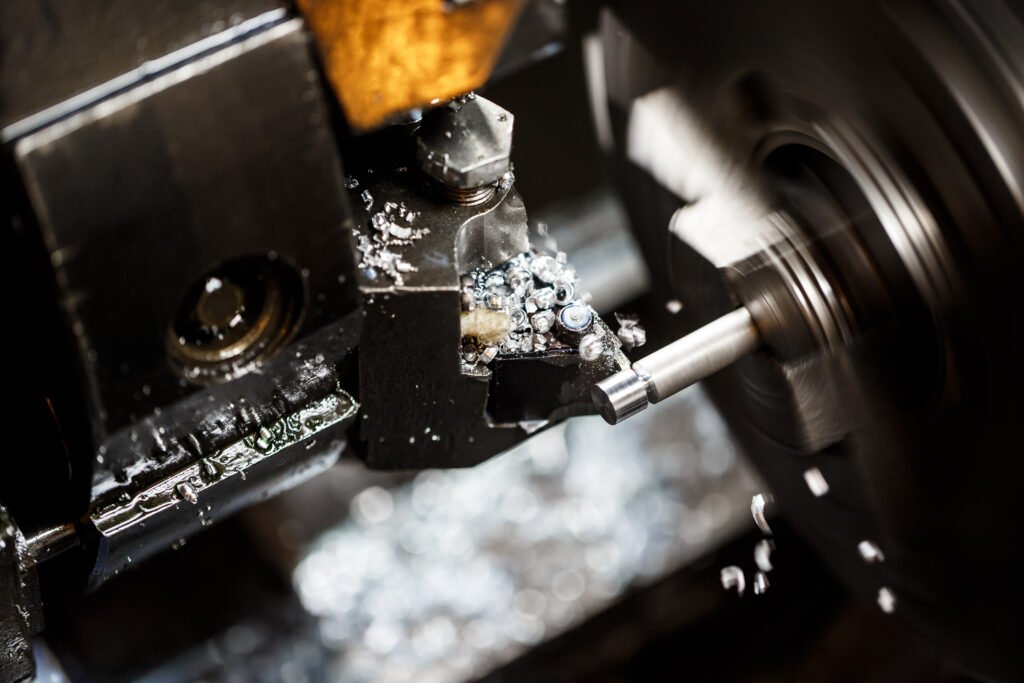

The manufacturing company “Altmanm” offers a wide range of services in CNC metal processing for various applications, from simple tools to complex components. CNC milling machines enable milling and engraving of surfaces of products in both 2D and 3D space. Numerical control systems are used to automate the milling process, which is a subtractive manufacturing method employing a rotating cutting tool for material removal. Our team of specialists is ready to handle orders of any complexity and ensure high-quality processing.

Services included:

Milling is used for:

- Medicine

- Aerospace industry

- Electronics

- Industrial equipment

- Energy industry

The milling process on CNC machines

- Convert all CAD files into code for processing.

- Designing parts in CAD.

- Setting up technological equipment.

- Manufacturing of parts.

- Processing of housing parts.

- Milling of shafts, gears.

- Volumetric milling.

- Milling of various surfaces.

- Reaming operations.

- Processing of cylindrical and conical surfaces.

- Cutting operations.

The cost of the work depends on:

- Order volume.

- The complexity of the works.

- Order processing time.

- The qualitative characteristics of the metal.

Milling of metal

There are several types of surfaces for which milling is suitable for machining on CNC machines:

- Horizontal milling operations.

- Inclined milling operations.

- Shaped milling works.

- Milling with other types of profile.

| Category | Parameters |

|---|---|

| Longitudinal | 800 мм |

| Transverse | 320 мм |

| Vertical | 420 мм |

| The working surface of the table | 1250 мм х 320 мм |

3-coordinate CNC milling machines

Similar to a lathe, it adds an additional degree of movement by rotating around a vertical axis, which makes it possible to produce more complex parts.

4x coordinate CNC milling machines

The 4-axis CNC milling machine is a numerically controlled machine that can move its tool in four directions.

5-coordinate CNC milling machines

The most advanced milling machine has two additional degrees of displacement due to the rotation of the working table and the spindle.

Portfolio

GOST R ISO 9001-2015

certification

Permissible coaxiality field ±0.02 mm

standard

3- and 5-axis CNC milling

technology

Acceleration of processing processes

maintenance

Execute order

> Submit Request

Contact the managers using one of the methods provided on the website.

> Technical task

Provide a drawing for calculating the cost of manufacturing the parts.

> Approval

To discuss the details of the order, sign the specification and contract.

> In manufacturing

Manufacturing the product according to the provided and approved drawings.

> Delivery

We will ship the order to Russia and CIS countries with favorable delivery terms.

For manufacturing companies and legal entities

Manufacture of high-precision parts in small to large batches

High precision positioning during parts processing

Efficient technologies and affordable prices with high quality

Quality control of finished parts and fast delivery

More than 200 staff members have undergone professional training

Our equipment park comprises over 100 modern machines

To submit a request

We hope that we can provide professional solutions to your problems. You can also get in touch with our engineers for further assistance.