Mechanical Processing

Metal Machining

There is a wide range of metalworking operations, which include several types of mechanical impact on metal to give it a certain shape: turning, milling, drilling, grinding. Modern multi-functional CNC metalworking centers are capable of quickly and accurately performing all these tasks according to the program, giving the parts the required configuration.

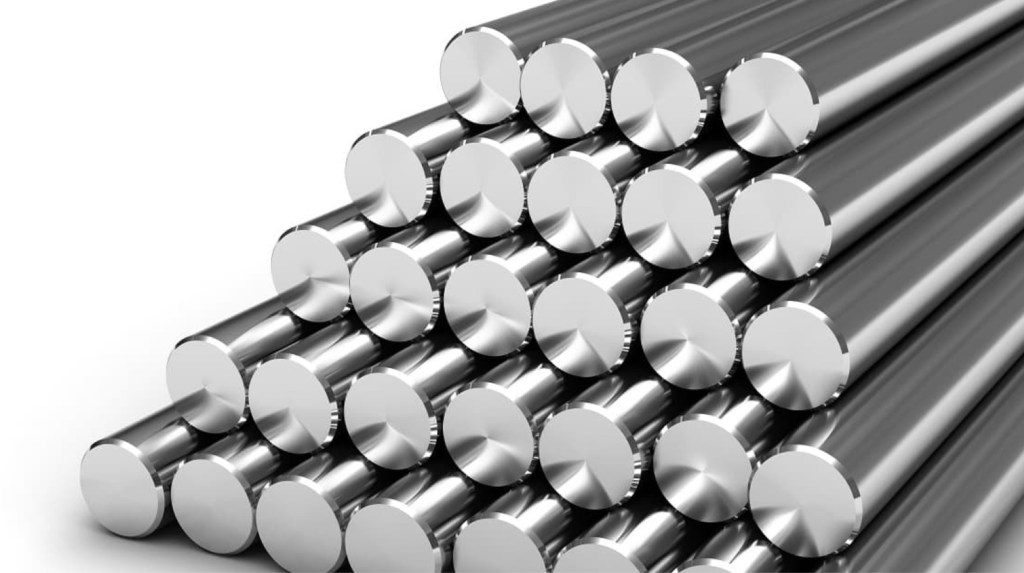

Processed metals

We offer machining services

What are milling operations used for

Milling is a widely used and sought-after machining method that involves shaping metal using a mill’s longitudinal movements on the workpiece. The mill removes excess material to achieve the desired shape. Unlike turning, where the workpiece rotates, milling involves linear movement of the workpiece while the mill rotates. This process allows for the creation of complex shapes and geometries. Various types of mills are used, including end mills, face mills, cylindrical mills, slot mills, keyway mills, disc mills, modular mills, and profile mills.

Milling is used for:

Our services include:

- Metal processing;

- Design and architecture;

- Mechanical engineering;

- Woodworking;

- Jewelry production.

The cost of the work depends on

- The volume of the order;

- The complexity of the work;

- The processing time of the order;

- The quality characteristics of the metal

- Machining of housing components.

- Machining of cylindrical and conical surfaces.

- Cutting operations.

- Reaming, countersinking, or facing of the product.

- Metal reaming.

- Milling of shafts, gears.

- Milling of various surfaces.

- Boring operations.

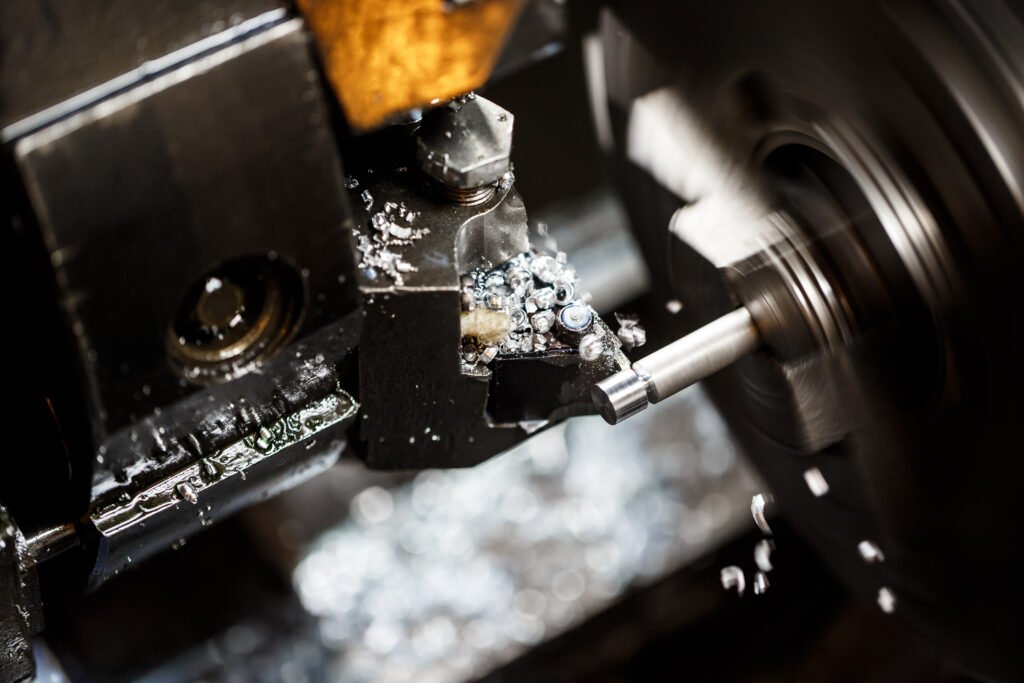

What is turning used for

Metal turning is a category of metal machining performed on a lathe, where a cutting tool is applied to a metal workpiece to remove layers of metal and shape it as needed. Turning is used for machining cylindrical, spiral, and screw-shaped parts, and it involves the use of various cutting tools.

Types of turning operations:

Our services include:

- Cutting of through and blind threads.

- Turning of cylindrical outer surfaces.

- Turning of conical surfaces.

- Machining of grooves, slots, and pins.

- Drilling of holes of various diameters and types of sections.

Стоимость работы зависит от:

- Order volume.

- Complexity of the work.

- Processing time for the order.

- Quality characteristics of the metal.

- Turning and milling operations.

- Turning of parts.

- Turning work on a universal machine.

- Turning work on a CNC machine.

- Manufacturing of non-standard parts.

- Turning of plastic.

- Turning of conical surfaces.

- Turning of shaped surfaces.

- Turning of non-ferrous metals.

- Turning of steel.

Why are grinding operations necessary

Grinding of metal is a type of abrasive processing that involves removing the top thin layer either with professional equipment or manually. The procedure helps to achieve the necessary dimensions, correct shapes, or smooth surfaces of parts. We use CNC equipment, which reduces the likelihood of errors, increases processing accuracy, and reduces the time required to complete the tasks at hand.

Milling is used for

Our services include

- Metal processing.

- Design and architecture.

- Mechanical engineering.

- Woodworking.

- Jewelry production.

The cost of the work depends on

- Manufacturing time.

- Type of grinding.

- Sketches and drawings.

- Surface area, parameters, and dimensions of the product.

- Material thickness, measured in millimeters for metals.

- Grinding and polishing of profiled pipes.

- Grinding and polishing of round pipes.

- Grinding and polishing of cold-rolled sheet metal.

- Grinding and polishing of hot-rolled stainless steel sheet.

- Grinding of flat surfaces.

CNC Milling Services

It is suitable for precise drilling, reaming, countersinking, and milling of planes, chamfers, grooves, surfaces, and threads of processed materials.

3-coordinate CNC milling machines

Basic technologies

3-axis CNC milling machines are used to create three-dimensional objects from metal, plastic, and other materials. They are computer-controlled and can be used to create a wide variety of objects. 3-axis CNC milling machines are based on the same principles as 2-axis milling machines. A 3-axis mill consists of two independent rotary axes and one linear axis.

4x coordinate CNC milling machines

Basic technologies

4-axis CNC milling machine is a computer numerical control (CNC) machine that can move its tool in four directions: up and down, left and right, forward and backward, and also rotate around one axis. This enables it to create three-dimensional objects by cutting material from a block of material. It can also aid in creating four-sided objects from flat material.

5-coordinate CNC milling machines

Basic technologies

5-axis CNC machines are suitable for specific applications, especially considering the number and direction of rotational axes. Five-axis machining is very similar to traditional three-axis machining, with the main difference being that the workpiece rotates using two additional rotational axes, providing greater cutting flexibility for milling or drilling.

Execute order

> Submit Request

Contact the managers using one of the methods provided on the website.

> Technical task

Provide a drawing for calculating the cost of manufacturing the parts.

> Approval

To discuss the details of the order, sign the specification and contract.

> In manufacturing

Manufacturing the product according to the provided and approved drawings.

> Delivery

We will ship the order to Russia and CIS countries with favorable delivery terms.

GOST R ISO 9001-2015

certification

Permissible coaxiality field ±0.02 mm

standard

3- and 5-axis CNC milling

technology

Acceleration of processing processes

maintenance

To submit a request

We hope that we can provide professional solutions to your problems. You can also get in touch with our engineers for further assistance.